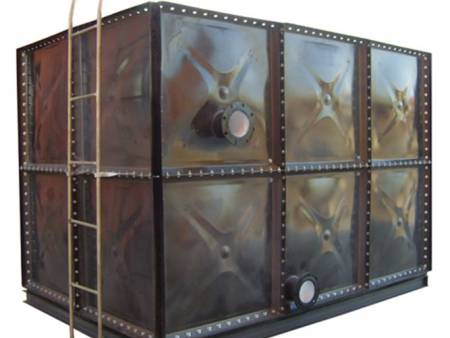

Enamel steel water tank

product description

The assembled composite enamel steel water tank is a standard block which is stamped into 1000mm×1000mm and 1000mm×500mm by Q235 steel plate. It is a kind of storage water supply equipment . It is assembled with a unique enamel formula and simmered at 850-900°C. A new type of water tank has a high mechanical impact resistance of the porcelain layer. It is 4-5 times stronger than the porcelain layer of general enamelware. It not only solves the phenomenon of porcelain explosion during transportation and assembly, but also has the advantages of acid resistance, alkali resistance, no leakage and no leakage. Before the enamel, the standard lining was evenly smashed inside and outside the standard block, which completely solved the anti-corrosion problem of the water tank and ensured the clean and hygienic water quality in the water tank. It is an ideal water tank for storing drinking water such as hot and cold water. According to the quality inspection of the glass enamel products of the Ministry of Light Industry and the identification of the Beijing Health and Epidemic Prevention Department, the physical and chemical indicators meet the government's drinking water hygiene standards.

The main purpose

The assembled storage enamel steel water tank has a water storage capacity of 1.0m3—300m3, which is mainly used for expansion and condensate tanks of heating systems; fire and storage water tanks; temporary storage tanks for building construction, geological exploration and national defense projects.

Installation and commissioning

● When constructing the civil works, the support should be made first. The joint between the water tank and the standard block at the bottom of the tank should be seated on the support.

●The installation of the water tank does not need to be welded, the standard block is drilled around, assembled on site, and the special food grade rubber strip is sandwiched between the standard blocks during assembly (when the water tank is used as the hot water tank, the rubber strip is changed to the heat-resistant rubber strip) to prevent leakage. It is then connected with galvanized bolts.

●When installing, the water tank box and the wall and the bottom of the box and the top of the box must have maintenance access. The box and the wall are not less than 0.7 meters. The bottom of the box and the top of the box are not less than 0.6 meters. Other weldments must not be welded inside or outside the water tank to avoid burning. Porcelain noodles.

● After assembly, close the outlet pipe and empty the valve, open the inlet pipe, and check the water until it is full of water. The water is not allowed to pass for 24 hours.

● The water tank should be cleaned regularly to prevent debris from rushing into the tank when testing water.