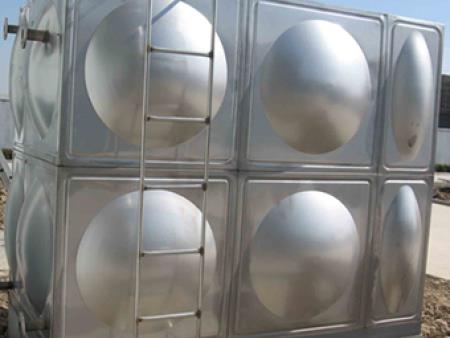

SUS304 stainless steel water tank

(1) Water storage equipment - Introduction to stainless steel water tank

The stainless steel water tank is another new type of water storage tool after the FRP water tank. Its products are made of all stainless steel plates. The shape is beautiful, economical and practical, and the main body is not bad. Compared with other water tanks, it has many advantages such as light weight, high strength, corrosion resistance, high temperature resistance, clean water, anti-seepage, anti-vibration, never moss, easy installation and easy cleaning. Stainless steel water tank is a special water storage equipment (commonly known as high water tank or low water tank) for engineering construction and high-rise residential water supply system. The stainless steel water tank is made of international common food grade stainless steel SUS304 plate, with a new concept design. In the production process, the CNC stamping technology is used to form the convex template, and the modules required according to the customer's size requirements are flexibly combined, and then the on-site assembly welding is completed. The indicators meet the industry standards, and the stainless steel water tanks meet the water quality standards and food hygiene standards in China's regulations.

(2) Product features

A stainless steel material has stable physical and chemical properties, no pollution to water quality, and ensures clean and hygienic water quality.

B The water tank has high strength, light weight, clean appearance, beautiful appearance and elegance.

C surface is smooth and beautiful, easy to clean

D Excellent corrosion resistance and good sealing performance.

E High impact resistance and strong seismic performance

(3) Product quality:

Imported stainless steel SUS304 first grade material, in line with OCr18Ni19 sanitary inspection standard, no rust, no long moss, no water leakage, keep clean and hygienic, safe and stable, service life is more than 15 times that of concrete water tank, and can be applied to cold water, clean water , boiling water, chemicals, solvents, etc.

(4) Scope of application

It is widely used in industrial and mining, enterprises, institutions, houses, hotels, tourism, restaurants and other buildings, as drinking water, fire water and food, medicine, health and other water storage facilities that require high water quality.

(5) Installation and commissioning

The stainless steel water tank base can be made of concrete strip beam or I-beam, and the inside is used with lacing. Each nozzle flange is a 1.0 MPa standard flange. When designing the water tank position, the designer should refer to the GB17051-1997 secondary water supply facility sanitary code. When the technical parameters or orientation of the water tank specifications are not suitable for actual use, the stainless steel water tank designer shall make a determination according to actual needs.

· Stainless steel water tank full of water experiment, no leakage for 24 hours;

· There is no leakage in the pipe joints, valves and related accessories;

· Observe whether the operation of the water supply system is normal;

· Check that the water disinfection system is working properly.

(6) Instructions for use of stainless steel water tank

A, fully enclosed, with the function of water, water, overflow, sewage, easy to install, just put the water tank in the designated position, connect the water pipe to use, maintenance is very convenient.

B. Stainless steel water tank, as a secondary equipment for storing domestic water, can only be used for domestic water (fire water), and cannot be filled with hydrochloric acid, sulfuric acid or liquid with high acidity and alkali content.

C. During use, do not place other heavy equipment on the top of the water tank. Do not use hard objects to knock or paint the water tank surface and pipe fittings. If there is any problem, please inform the factory technical maintenance personnel and repair the welding personnel. The requirement is to specialize in argon. Professionals in arc welding work should discharge water during maintenance.

D. Maintenance personnel should regularly observe the use of internal and external main parts and accessories in the water tank every month, and report problems to the manufacturer in time.

E. Do not open the water tank inlet cover to prevent secondary pollution of water quality. The water tank should be cleaned and disinfected 1-2 times a year.